About KAAP

Kobe Aluminum Automotive Products (KAAP) is part of the Kobe Steel Group, which is known internationally by the KOBELCO brand and for quality materials and machinery.

KAAP began production in Bowling Green, Kentucky, in 2005. Although we were new to the United States, we have been serving the aircraft and automotive industry in Japan since 1937. Our market leadership in Japan attests to the quality of the aluminum automotive parts we manufacture.

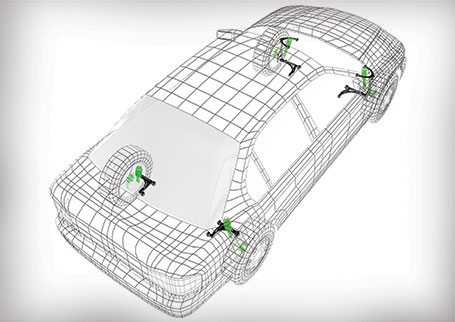

As the importance of protecting the global environment mounts, automakers have been working to reduce the weight of automobiles in order to achieve goals for reducing CO2 emissions (i.e., improve fuel economy). Aluminum parts forged by KAAP are light weight. By contributing to the overall reduction in weight of the automobile, our products help consumers save through lowered fuel consumption, and ultimately are better for the environment.

We are proud of what we do at KAAP. We are not only forging top quality products, we are forging a new era in automotive manufacturing - marrying technology with the human issues that improve quality of life for all of us.

Dedicated line for Aluminum Forged Suspension Products

State of the art manufacturing facilities

- Continuous Casting Machine

- 6300 ton Mechanical Forging Presses

- 300 ton Mechanical Trimming Presses

- Continuous Heat Treatment Furnaces

- Automatic Penetrant Inspection Lines

KAAP Advantages

Weight Reduction

Achieved through use of KAAP's own high strength aluminum alloy and expert product design analysis.

Reliability

Achieved through ISO9001 - certified attention to consistent quality.

Cost Reduction

Achieved through enhanced material yield ratio, reduced forging cycle time, and total in-house recycling of scrap.

Globalization

Achieved through production in the United States, Japan, and China, to serve auto markets worldwide.

KAAP Quality Policy

Kobe Aluminum Automotive Products is committed to producing quality products, consistently meeting customer expectations, commitment to satisfy statutory, regulatory applicable requirements and striving to increase customer satisfaction through continual improvement of products and services, and the KAAP quality management system. KAAP is certified and registered to the ISO 9001 Quality Standard.

KAAP Quality Scope

KAAP is committed to improving customer satisfaction and maintaining our company trust by supplying aluminum suspension components as a light weight solution that meets our customer requirements.

KAAP will continuously improve our operational process through standardization activities and our Quality Management System that complies with the requirements of IATF 16949 for the following scope: Through our parent company Daian Works Japan, the design and manufacturer of forged aluminum products and cast aluminum bar.